Company History

Three Generations

Anton Ehrle (1894 – 1961)

Anton Ehrle was born in Voggenreute, Germany in 1894. He learned the blacksmith‘s craft and passed his examination for master craftsman‘s diploma in 1927. He thus laid the foundation stone for the still continuing interest of the EHRLE sons in metalworking.

Oskar Ehrle (1922 – 2011)

Oskar Ehrle was born in Bad Schussenried, Germany in 1922. After elementary school he completed an apprenticeship as a hand molder from 1936 to 1939. During World War II he was drafted as a pilot of rescue airplanes. In 1945, he was taken prisoner by the Russians and transferred to Werche-Tura in Siberia.

Marked by hunger and illness he returned to his hometown by the end of 1947. After recovery from his imprisonment, Oskar Ehrle attended Engineering School in Constance, Germany from 1950 to 1953 and graduated as a „Mechanical Engineer“.

As early as in 1959 he developed and designed one of the first steam jets for WAP - the DR 600.

In 1961 he founded the company EHRLE in Illertissen, Germany.

Reiner Ehrle (*1959)

In 1959 Reiner Ehrle was born in Illertissen, Germany. After elementary school he completed secondary school in 1975 and was awarded the secondary education certificate. After passing his A Levels in 1977, he started his one-year traineeship in the USA before attending the Technical College in Ulm, Germany from 1979 to 1983 where he received his diploma for mechanical engineering.

During his subsequent studies in business economics in Pforzheim, Germany his was able to deepen his knowledge in economics. In 1984 he entered his parents' company in Illertissen, Germany. Owing to his comprehensive knowledge in mechanical and industrial engineering he succeeded in gradually expanding his parental company from a small business to a medium sized company with subsidiaries in other European countries.

Today, the entire EHRLE Group employs a workforce of more than 200 employees.

As Time Goes By

-

1959

The First Steam Jet

Oskar Ehrle develops and designs the first steam jet DR 600 on behalf of "WAP - Guido Oberdorfer".

-

1961

The cornerstone is laid

The company EHRLE is founded by Oskar Ehrle. Therefore, a manufacturing plant is built in Illertissen.

-

1966

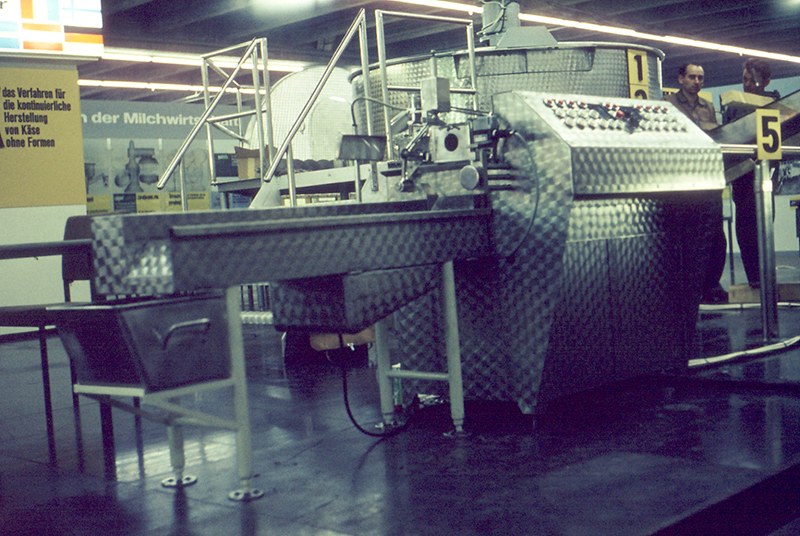

Fully Automated Cheese Cutter

EHRLE constructs a fully automated cheese cutter with salt spray chamber on behalf of Werner & Pfleiderer company (Stuttgart).

-

1970

Jet 750

The serial production of the EHRLE Steam Cleaner Jet 750 begins. This product is equipped with a single-piston pump, designed by Oskar Ehrle.

-

1971

Cold Water High Pressure Cleaner

Due to the evolution of high pressure pumps the first cold water high pressure cleaners are manufactured in series.

-

1972

First Hot Water High Pressure Cleaner

First hot water high pressure cleaner EHRLE HDW 750 goes into production. With this tool the transition from steam jets to the nowadays popular hot water high pressure cleaners is initiated.

-

1973

First General Distributor

The first general importer is established in Switzerland. The new high pressure cleaners are used in many industries and enjoy a good reputation.

-

1974

Swimming Pool Heater

A bathwater heater for swimming pools with horizontal heat exchanger, „Iller Thermal“ is built.

-

1975

Model Change

Further development and model change of the hot water high pressure cleaners.

Several special accessories with combinated high pressure and steam nozzles are launched on the market.

-

1978

Facelift

Facelift for the hot water high pressure cleaners. The drawbar is replaced by a swivel caster with push bar. The model range is extended by powerful devices with a high water performance up to 1.800 l/h.

-

1979

First Self-Service CarWash

Development and design of the first self-service CarWash (Outdoor Rack) with water-softener and warm water heating boiler plant as a precursor of today's self-service CarWashes. With this invention the success of EHRLE's CarWash production was founded.

-

1982

EHRLE Turns Red

A new corporate identity is launched. In this context, the company gets his new corporate color, the EHRLE red.

-

1984

Consumer Cold Water High Pressure Pump

Manufacturing and distribution of the first consumer cold water high pressure cleaner. This pressure washer is sold successfully both domestically and abroad.

-

1985

CNC Controlled Machine Tools

Model change for hot water high pressure cleaners. For the first time CNC controlled machine tools are used for serial production.

-

1998

CarWash Installations Complete

EHRLE is now positioned as a full-service provider of EHRLE of complete CarWash equipment such as precast concrete plates and steel constructions for the wash bays.

-

1999

Transparent Tanks and Plastic Covers

Model change for the hot water high pressure cleaners. Use of transparent tanks and a plastic cover for the first time.

The devices are now produced on a semi-automatic production line.

-

2000

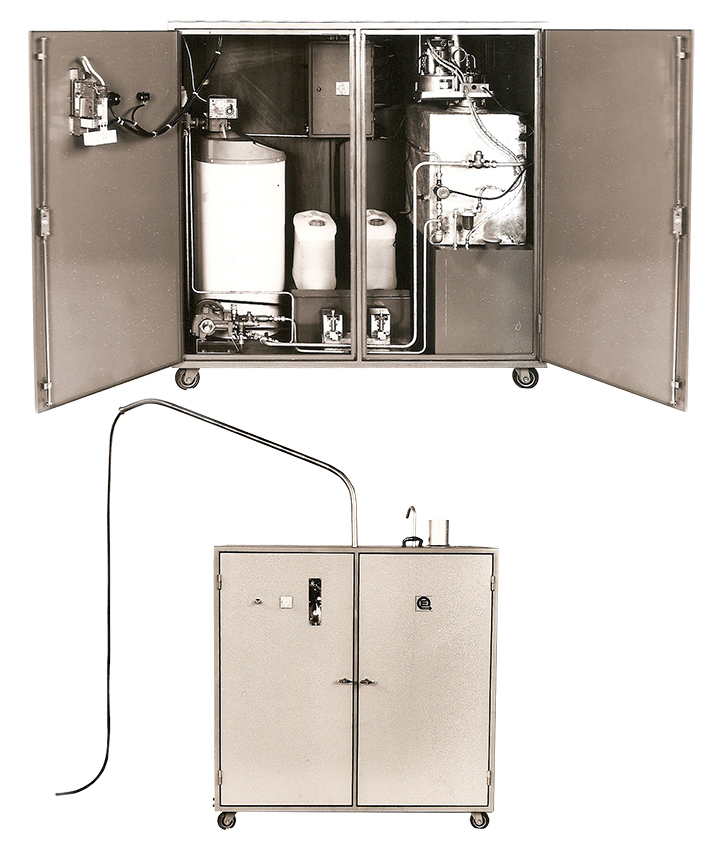

Cold Water Cleaners, Stationary

The first cold water high pressure cleaner as compact machine is developed.

Due to the great success of the stationary cold water high pressure cleaner, EHRLE starts to develop and manufacture an new hot water high pressure cleaner for special use in the industry.

The customers area and the fields of application expand permanently.

-

2001

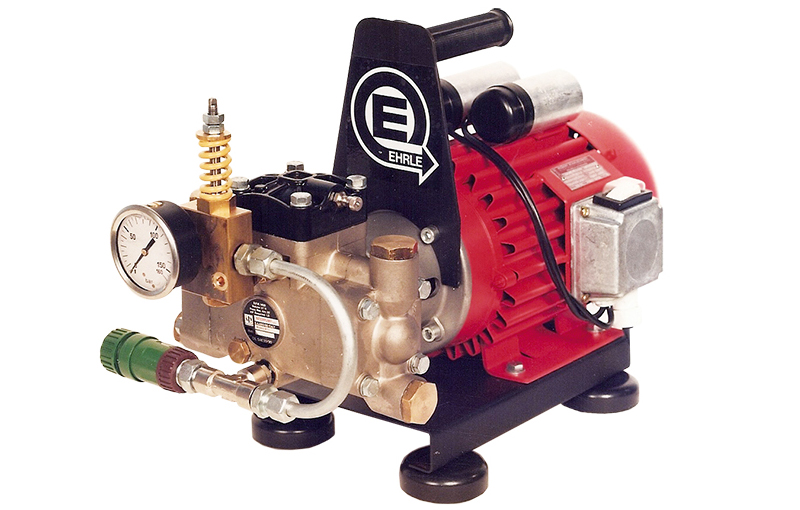

Triplex-Plunger Pumps

Model change in the cold water high pressure cleaners. Modern triplex plunger pumps with a pressure range up to 200 bar and plastic reinforced machine coverings are established in the production.

-

2002

Unplugged

Development and design of engine driven hot water high pressure cleaners. With this the high pressure cleaner is no longer current-dependent and can be used anywhere.

-

2003

EHRLE International

In order to the international breakthrough of the CarWash Outdoor Series, EHRLE offers now multi bay carwash installations with up to 12 wash bays,where all technic equipment is installedin a ready to use precast concrete technic-container.

-

2004

New Design for the Consumer Tools

Model change and a new design for the consumer cold water high pressure cleaners.

-

2005

ETRONIC I & Design Pro

Introduction of the ETRONIC I control. All functions are now electronically monitored and evaluated.

Model upgrading of stationary hot water high pressure cleaner. The stationary high pressure cleaners are also available with complete stainless steel housings.

EHRLE develops the "DesignPro" Steel Structure for self-service carwashes. The design has been protected by law in throughout Europe. This ultra-modern steel construction is a trademark of EHRLE from now on.

-

2006

Self-Service Vacuum Cleaners

Production of self-service vacuum cleaners in stainless steel or powder coated corrosion proofed cabinet. The special feature is the overhead suction hose system for a easy handling for the customers. The suction hose doesn't get dirty due to the fact that it never touches the ground.

-

2007

JetWash & JetWash Plus

In order to complete the manufacturing program of the self-service CarWash units for smaller business EHRLE introduces the series JetWash and JetWash Plus. This equipment is especially designed for gas-stations and car repair-shops.

-

2008

ETRONIC, Second Edition / Sweepers

Model upgrading of mobile hot water high pressure cleaners. New ETRONIC II control offers additional control and maintenance advantages. All machines are electronically monitored and evaluated.

Start of distribution of sweepers for commercial use. These sweepers are offered in different sizes up to professional ride-on sweepers. Customers can choose between electric or gasoline driven versions.

-

2009

KD 4x4 & SmartWash

Production start of the SmartWash and SmartWash Plus modules. These single bay self-service stations offer a professional and cost effective solution and is specially designed for gas stations with already existing wash bays.

-

2010

EHRPORT

Distribution start of the RollOver portal wash system EHRPORT. These fully automatic rollover CarWash machines are supplementing the self-service CarWashes. The customer now can choose between a touchless manual, or a fully automatic brush cleaning of his vehicle.

-

2011

Wash and Care Center

The first complete wash and care-center becomes reality. The EHRLE Design Pro Steel Structure combines self-service car wash bays with automatic rollover centers.

-

2013

KD 2 x 2

With the cold water high pressure cleaner KD 2 x 2 a new, more compact two wheeled version of the KD 4 x 4 enters the market.

United Kingdom

United Kingdom

All Countries

All Countries

Belgium

Belgium

Germany

Germany

France

France

Greece

Greece

Latvia

Latvia

Austria

Austria

Poland

Poland

Romania

Romania

Serbia

Serbia

Switzerland

Switzerland

Slovakia

Slovakia

Czech Republic

Czech Republic

Hungary

Hungary

United Kingdom

United Kingdom

Netherlands

Netherlands

Azerbaijan

Azerbaijan

Georgia

Georgia

Iran

Iran

Kazakhstan

Kazakhstan

Australia

Australia

New Zealand

New Zealand